New type of Kevlar heading to ISS in October for space debris protection tests (Image Credit: Space.com)

A next-generation space debris protection material is readying for a test trip to the International Space Station.

The material, a sibling of the space-blanket polymer Kevlar, has been developed by chemical giant DuPont and tested by NASA at its White Sands Test Facility (WTSF) in New Mexico. The tests showed that the new Kevlar “EXO” material provides better protection against space debris impacts while being significantly lighter than conventional Kevlar.

“We were able to reduce the weight by as much as 40% and still have it pass the tests for orbital debris needs,” Jill Clements, DuPont’s global business development manager, told Space.com.

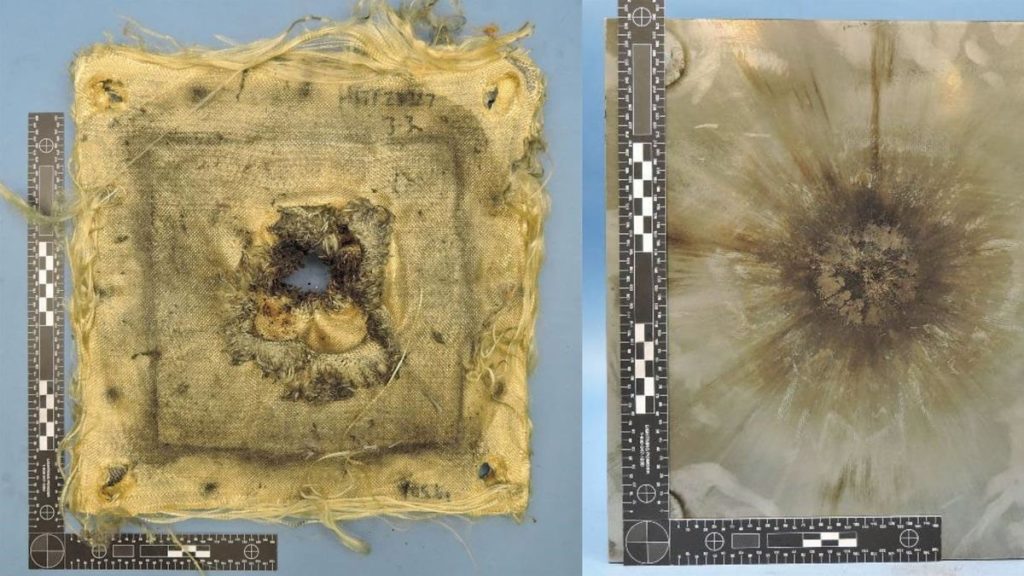

During the tests at WTSF, NASA researchers shot aluminum bullets 0.4 inches (1 centimeter) wide from special cannons at the speed of 4 miles (6.5 kilometers) per second at square targets 12 by 12 inches (30 by 30 cm) in size. The simulated debris fragments couldn’t pierce through the test shields even when a lower amount of the protective material was used compared to currently available space debris guards.

Related: The Kessler Syndrome and the space debris problem

DuPont is now preparing samples of Kevlar EXO for a mission to the International Space Station (ISS) to verify how the material withstands the space environment.

“We will be doing atomic oxygen and UV [ultraviolet radiation] exposure testing,” Clements said. “We don’t at this point plan to use it for debris protection, because all the testing has been done on the ground.”

Several patches 2 by 2 inches (5 by 5 cm) in size will be shipped to the ISS aboard a SpaceX Dragon cargo capsule in October and attached to the orbiting lab’s exterior, where they will remain for several months.

DuPont introduced Kevlar EXO in April 2023, describing the new material as “the most significant aramid fiber innovation in over 50 years.” Aramids are a class of sturdy, heat-resistant synthetic fibers, a family that includes the iconic Kevlar. Developed in 1965, Kevlar has been used in a variety of applications, including bullet-proof vests, combat helmets and protective clothing. In space, Kevlar has served as a thermal insulator for satellites and, since the 1990s, as a key component in space debris protection systems.

Clements said Kevlar EXO is “a different type of material” than standard Kevlar, a sort of a “cousin of the traditional aramids.” The superior strength of the new material, which enables the overall mass reduction in space debris shields, will be a huge boon for the space sector, Clements thinks.

“We’re hearing from the industry that it really is game-changing in the amount of weight it’s allowing companies to take out from their orbital debris systems,” said Clements. “First, getting things off the ground is expensive, and second, companies don’t want to waste their mass budget on space debris protection. They want to use it for their payload.”

She said the new material will not only help satellite manufacturers and builders of crew and cargo-carrying spaceships; it could also protect future inflatable space stations in low Earth orbit, as well as habitats on the moon and Mars. Clements foresees that Kevlar EXO will be indispensable for future moon and Mars exploration.

“As we look to get back to the moon and eventually to Mars, you just can’t take enough weight out to get people to the moon plus supplies in any kind of large quantity,” Clements said. “You have to compensate somewhere, but at the same time, you need to get them there safely. We hope to be a valued part of that industry.”