How bacteria are inspiring the next generation of space-borne lasers (Image Credit: Space.com)

Solar-powered lasers that run on the photosynthetic machinery of bacteria could one day provide a low mass, simple and sustainable means of providing power in space, replacing the usual heavy lenses and complex electronics that aren’t very cost-effective to launch.

“Our plan is to use photosynthetic structures extracted from bacteria, and the idea is that you can grow them and keep replenishing material, you don’t need to maintain a supply line from Earth,” Erik Gauger, a professor of photonics and quantum science at Heriot Watt University in Edinburgh and leader of the new project, told Space.com.

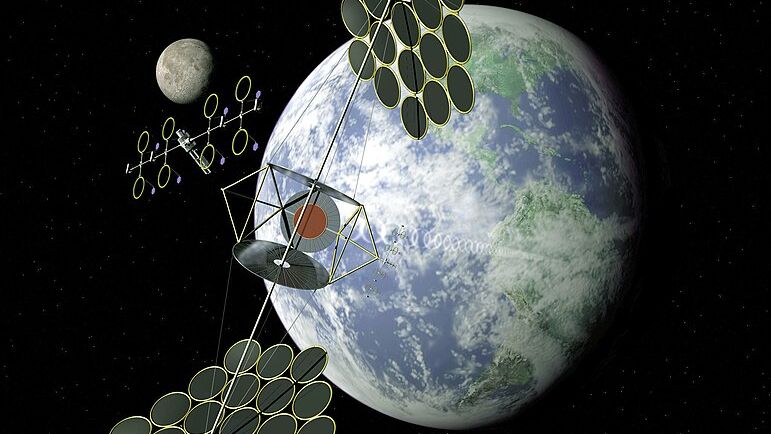

As the number of satellites in our planet’s orbit continues to grow, scientists have started to focus on how to provide power for these satellites in the long run. With better power mechanisms, it’s likely we’ll be able to increase the lifespans of spacecraft. One potential solution is power beaming — using solar arrays to convert the sun‘s light into lasers or microwaves that can be beamed towards a stricken satellite to power it up via a receiver on the side of that satellite.

Early in 2023, the first power-beaming tests from space successfully transmitted low-power microwaves, amounting to no more than a few milliwatts, from the Space Solar Power Demonstrator satellite to a ground station at Caltech. In 2025, Japanese researchers aim to achieve a similar feat.

Related: Scientists beam solar power to Earth from space for 1st time ever

However, solar arrays can be big and bulky, and their complex designs and circuitry would mean any orbiting solar farms would require regular replacement or repair. It’s probably better to find a more sustainable and self-sufficient method, and researchers working on the APACE project think they have a solution. With this project, they seek to adapt the molecular structures that allow bacteria to photosynthesize toward a laser system that could be used in space.

“Our key idea is to replace the concentrating optics with the photosynthetic antenna complexes,” said Gauger.

APACE involves researchers from the U.K., Germany, Italy and Poland, and is being funded by the European Innovation Council and Innovate U.K. to the tune of 476,000 euros for phase 1. Gauger, as APACE’s project manager, explained what phase 1 involves: “For the moment, trying to do the proof of principle on Earth in our laboratories, and we will be testing it under simulated space conditions towards the end of the project.”

This would see the team extracting and experimenting with the molecular antennas to determine which species of bacteria produce the most usable ones for solar-powered spacecraft. The researchers will also explore nano-engineering artificial antenna structures to compare how efficient and usable they are compared to the organic variety.

Some extremophile bacteria, for instance, are able to thrive in very low-light conditions by having molecular antennas that are able to absorb practically every photon that falls on them and direct the energy to wherever it needs to go in the bacteria’s cellular biology.

The APACE project is looking to adapt such bacteria, extracting their antennas and using them to absorb sunlight. The solar energy would then be diverted into the laser mechanism. Lasers operate by using a “gain medium” inside the laser cavity. When photons interact with the gain medium they generate more photons — what is called stimulated emission — amplifying them, until there’s enough to produce an intense and coherent beam. The team is looking at possibly using neodymium nano-crystals as the gain medium, and sunlight gathered by the bacteria’s photosynthesizing antennas will provide the photons to get the laser started and then maintain its activity.

The bacteria could be grown in space, perhaps on the International Space Station or on a satellite, removing the need for continual launches from Earth to maintain and replace old solar arrays.

However, as Gauger said, actually launching a prototype into space would require a lot more funding and depend upon phase 1 being successful.

At this stage, the advantages of a successful version of the prototype are not necessarily efficiency, although that might come later. A typical silicon-based solar panel converts sunlight into electricity with an efficiency of about 30%, generating a few hundred watts per square meter. Although the bacteria from which the photosynthetic antennas are being adapted have an efficiency approaching 100%, the organic solar arrays being designed as part of the APACE project will only manage to convert 10–15% of sunlight into power.

Although this is much poorer than what nature does, “Maybe that’s not surprising since evolution has optimized it over a long time,” said Gauger. “We don’t quite know exactly why photosynthesis is as efficient as it is, and we’re not as good at moving around energy at the molecular level with artificial structures, and our materials are not as strongly absorbent.”

Limitations aside, APACE will still provide significant advances. “It’s a very different architecture,” said Gauger. With a typical silicon-based solar cell, the energy is collected but then something has to be done with it, using electronic components, to turn it into something usable. “In our case, we are trying to do this without anything electrical — without a battery; without circuitry.” The biological, photosynthesizing apparatus automatically converts the sunlight into a laser without needing all that machinery.

And, it should be mentioned that the sky is the limit when it comes to the potential of this technology. Should it prove successful, then by virtue of being a simpler, self-sustaining technology that doesn’t require frequent space launches carrying heavy payloads, it could bring the cost of power-beaming down. It needn’t stop at just powering up satellites in Earth orbit, either; it potentially could be used to beam power down to bases or vehicles on the moon or Mars someday.

“It could be extended in capacity in space by growing more bacteria and manufacturing it there, rather than needing to ship it out,” said Gauger. “Some of the engineering problems are probably a little bit down the line, but that’s the long-term vision.”