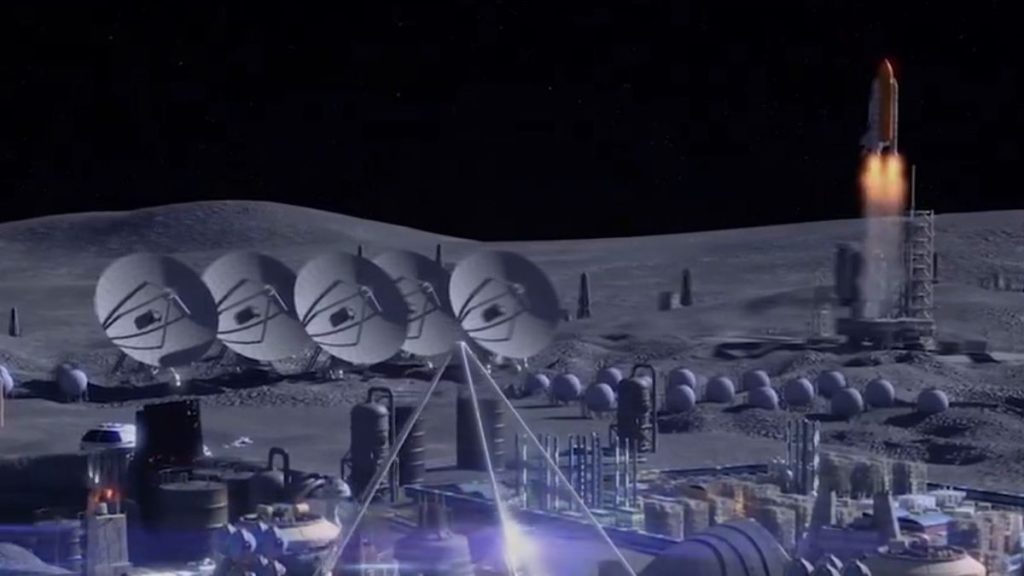

Building blocks: How China plans to make bricks on the moon for lunar habitats (Image Credit: Space.com)

Chinese scientists are developing the capability to build a moon base made of bricks formed from lunar soil.

A recent video from China Central Television (CCTV) shows an animation of a robot working to construct a lunar habitat known as a “moon pot vessel.” Alongside the videos, scientists are conducting concrete experiments to make the moon habitat a potential reality.

The Tianzhou 8 resupply mission launched toward China’s Tiangong space station on Nov. 15 with a range of bricks made from lunar soil simulant among its cargo.

Transporting things to the moon is immensely expensive and challenging, so using materials already present on the moon, known as in-situ resource utilization, offers a way to greatly save costs. Using lunar regolith to make bricks could transform the possibilities for constructing lunar habitats.

Related: China to test lunar-soil bricks in space to pave the way for its planned moon base

The test bricks will be placed outside Tiangong to be exposed to cosmic rays and large temperature changes for three years. The bricks were made with five different simulated lunar soil compositions via three distinct sintering methods, in order to assess their degradation over time and which could provide the best solution for a habitat.

“Back in 2015, when we started exploring whether 3D printing could be used to build a lunar base and what materials could be used, it felt like a fantasy that is incredibly distant,” said project leader Ding Lieyun, of the Chinese Academy of Engineering. “But as we keep working, our understanding has deepened, and we have realized that it is not just our team making efforts. Scientists from all over the world are tackling this challenge together.”

“For example, when it comes to energy issues, some experts told us, ‘You don’t need to worry about energy. There are specialized teams working on that. You’ll just use their results when the time comes,'” Ding said. “That realization has served as a big step forward. This is why interdisciplinary collaboration is so important. When these forces come together, they create something truly extraordinary.”

Ding’s team is working on various challenges such as materials, structure and requisite technology.

Lunar soil has been found to be a mix of rock fragments, minerals, glassy particles and other materials, varying from region to region across the surface of the moon. On Earth, volcanic ash from the Changbai Mountains in northeast China is considered close to the lunar soil composition and has therefore been used to create simulated lunar soil for experiments.

As the composition of lunar soil varies, so does its melting point. Higher temperature processing risks vaporizing low-melting-point minerals, leaving voids in the material, while lower temperature processing could leave higher melting-point minerals unbonded, creating weaknesses. It is with such challenges that Ding and his team are grappling.

Ding believes that this work will not only support lunar exploration, but could also lay the groundwork for future missions to more distant destinations, including Mars.

The next step will be the Chang’e 8 lunar south pole landing mission in 2028. Chang’e 8 will carry a robot that will test 3D-printing techniques to make a brick out of lunar regolith. This will be a precursor mission to China’s plans to establish its International Lunar Research Station (ILRS).