Astrocast and CEA’s low-cost, bidirectional communication module includes areas not covered by terrestrial networks (Image Credit: Sat News)

CEA, a technology-research organization, and Astrocast, a leading global satellite Internet of Things network operator, have announced their successful collaboration on a low-cost, bidirectional communication module that enables corporations to communicate with their remote assets in areas not covered by terrestrial networks.

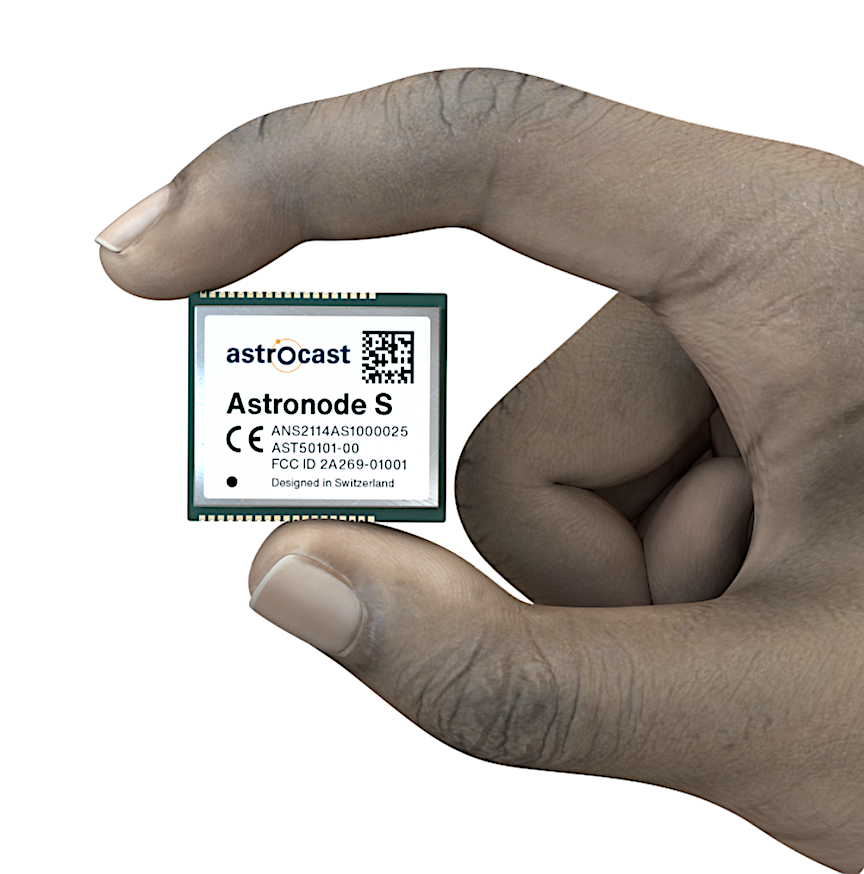

The module’s L-band chip, based on a new architecture developed by CEA-Leti, is a key hardware component that enables Astrocast customers benefit from cost-efficient communication with their assets in the field through its network. It was completed earlier this year in an expedited project between the research institute and Astrocast, and is embedded in Astrocast’s RF module, called Astronode S.

The chip’s architecture is split over the RF core and digital processing and control units. It is fully optimized to support Astrocast’s dedicated bidirectional ground-to-satellite protocol and provides an optimal trade-off between link budget and low-power and low-cost constraints. The chip also embeds all Low Earth Orbit (LEO), satellite-specific features such as satellite detection and robustness to Doppler shift. The low-power, compact, surface-mount Astronode S module for highly integrated, battery-powered IoT systems offers a total cost of ownership up to three times lower than traditional satellite IoT alternatives.

The miniaturized, surface-mount module communicates with terrestrial devices via Astrocast’s constellation of LEO satellites. Using the L-band spectrum, the network primarily targets maritime, oil & gas, agriculture, land transport and environmental applications in which ubiquitous coverage is required.

Laurent Vieira de Mello, COO Astrocast said, “Terrestrial IoT networks cover only about 15 percent of the planet, which leaves vast remote and rural areas where our global satellite network provides coverage that is crucial for our target markets. Leveraging its expertise embedded in a preliminary version of the RF chip, CEA-Leti developed its chip and delivered the final prototype to meet our requirements and time-to-market goals. They managed the chip technology transfer to our industrialization, qualification and production partner.”

The project’s critical time-to-market window was managed through a flexible collaboration model covering both prototype and industrialization phases.

Michel Durr, business development manager at CEA-Leti commented,“An accelerated time-to-market goal drove this project from the outset. We pioneered this RF technology in 2019, and our team customized it for Astrocast up to production in only three years.”

CEA-Leti’s industrial tester used for characterization was key to accelerating from prototype to production, which enabled prototype characterization in parallel on the tester and in the lab, Durr explained.

Michel Durr added,“This process provided a short-loop debug capability with all skills available at CEA-Leti, and enabled us to deliver fully validated inputs to Astrocast’s industrialization partner for an easier industrial test-program development.”