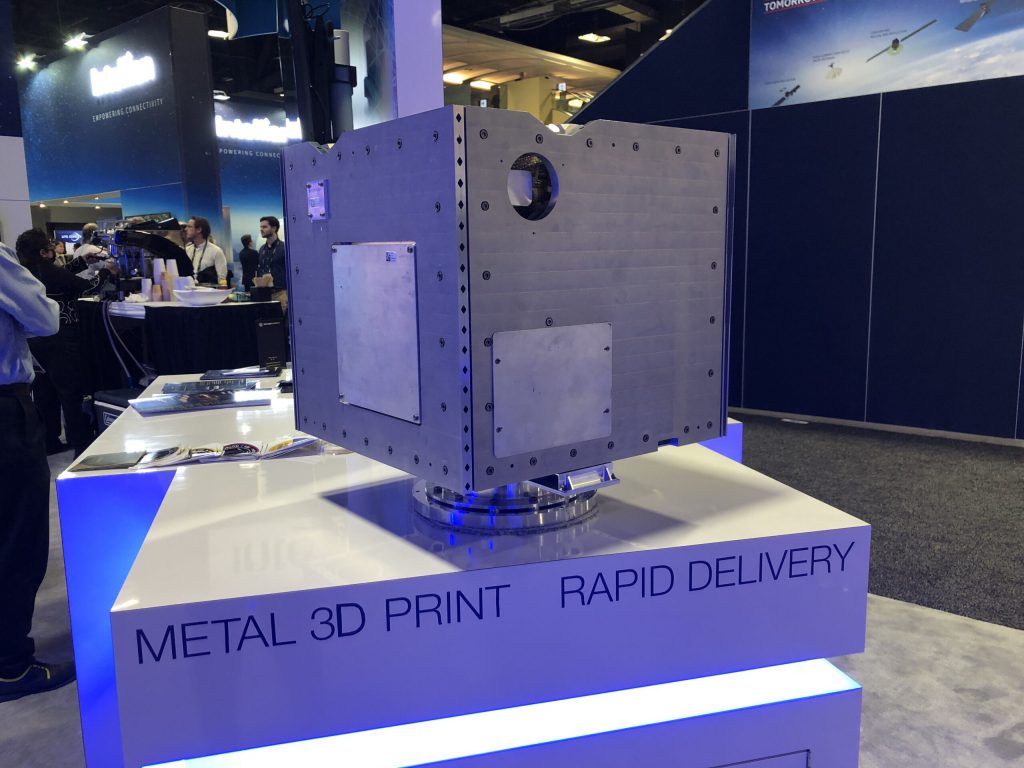

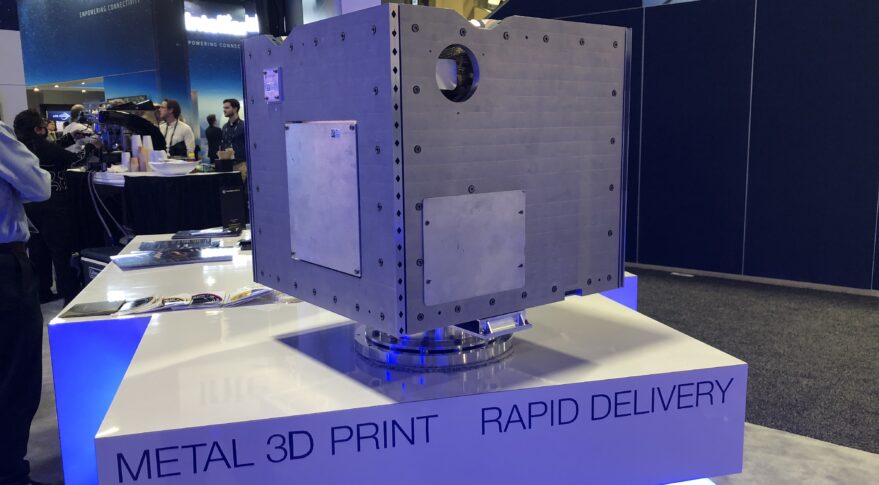

Millennium Space to launch to orbit a 3D printed satellite structure (Image Credit: Space News)

WASHINGTON — Millennium Space Systems plans to launch to orbit a 3D printed metal flight structure the company intends to use to build its next generation of satellite buses.

About the size of a small dorm refrigerator, the structure has been tested in simulators and the next step is to demonstrate it can withstand the stresses of space launch, Millennium Space CEO Jason Kim told SpaceNews at the Satellite 2022 conference.

“At this point it’s space qualified but we want to get over the perception hump that it hasn’t flown yet,” said Kim. Once it’s flown to space it is likely to generate more interest from customers, he said.

Since Millennium Space was acquired by Boeing in 2018, the company has increased investment in 3D printing technology to accelerate satellite production, Kim said. Boeing specializes in large spacecraft and Millennium focuses on smaller satellites, below 1,500 kilograms.

A pathfinder satellite with some 3D printed components flew to orbit successfully in 2018 but the technology is now far more advanced, he said. “The next logical step was to move away from polymer 3D printing to metal 3D printing.”

The flight structure can be printed it in less than 100 hours, he said. By comparison, traditional manufacturing with honeycomb aluminum panels takes about six months. “The integration time that usually takes days is down to hours, because everything just fits the first time, due to software defined design.”

Kim said the structure will launch as a rideshare payload in the near future as soon as the company can secure a ride. It will not deploy as a functioning spacecraft but only to qualify the structure.

“The hardest part of the design for a structure is withstanding the launch vibration and loads,” said Kim. “Once it gets on orbit there’s nothing really impacting the structure other than micro meteorites.”

It the space test is successful, Millennium plans to start offering satellite buses with the 3D printed structure, Kim said. There are cost benefits but most of the payoff is in the shorter production cycle.

Millennium Space currently has a backlog of about 50 satellites, said Kim. To grow, the company needs to be able to mass produce hundreds or thousands of satellites and 3D printing a major contributor to that goal, he said.

The company’s primary customer is the U.S. government. A potential opportunity is the Defense Department’s internet-in-space constellation being built by the Space Development Agency. SDA selected three vendors to produce 126 satellites to launch in 2024 and intends to solicit bids also in 2024 for another large batch of satellites.

“The Space Development Agency, the Space Force, the intelligence community, they all have very strict, stressing requirements,” he said. “This capability we’re developing is very much aligned to their kinds of missions.”

Millennium Space next week will unveil a new facility in El Segundo, California, with advanced tooling and test equipment “that is going to help us deliver these systems at a fast rate and high volume,” Kim said.