Surrey Satellite Technology Ltd. (SSTL) and Oxford Space Systems (OSS) have confirmed a partnership to build and launch an OSS Wrapped Rib antenna mounted to an SSTL CarbSAR satellite.

The In Orbit Demonstration mission advances both companies’ abilities, with OSS gaining space heritage, and SSTL building its ability to integrate capability from new suppliers. The work has been jointly funded by OSS, SSTL, Airbus Defence and Space, the National Security Strategic Investment Fund (NSSIF — HM Government’s corporate venturing arm for national security and defence technologies) and the MoD, and is proving a ground breaking Synthetic Aperture Radar (SAR) concept that may be of significant interest to UK defence intelligence, surveillance and reconnaissance (ISR) strategies in the near to medium term future.

Surveillance, change detection and “big data” analytics applications are driving interest in spaceborne SAR data, to support day/night and all-weather imaging at a rate faster than can be achieved with any individual satellite. This drives demand for much smaller radar satellites that can be launched within a limited launch volume in groups, however it is still desirable to retain a large antenna for better quality imagery.

Having a large, scalable, stowable and lightweight, reflector antenna provides a number of benefits in designing small radar satellites for particular applications. A reflector antenna can also significantly simplify the radar electronics, making it ideal for implementing radar on much smaller spacecraft such as SSTL’s CarbSAR platform.

The Oxford Space Systems Wrapped Rib Antenna for Synthetic Aperture Radar (SAR) enables high resolution imaging from smallsat EO missions, irrespective of weather conditions or daylight. These antennas deploy carbon-fiber ribs from a central hub to form a 3m diameter parabolic dish supporting a high performing metal mesh reflector surface.

This UK developed, antenna technology has a uniquely compact, stowed configuration and achieves a highly, cost-efficient performance when deployed in orbit. The antenna has successfully completed an extensive ground based test program, including a radio frequency (RF) test campaign and is now ready to demonstrate its performance in orbit.

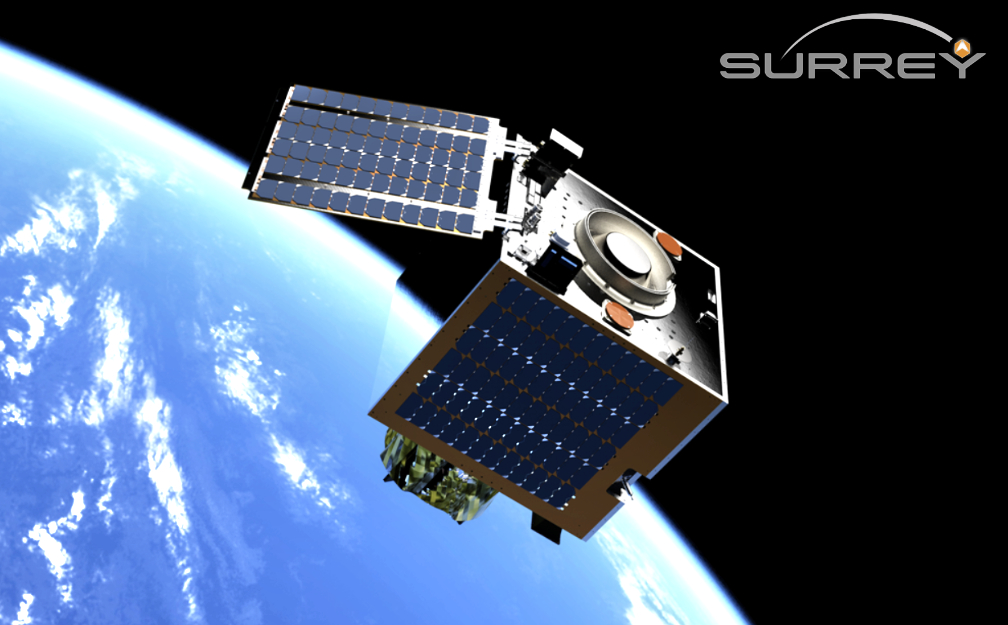

Carbonite is the latest in a long range of 100 kg. class smallsat platforms that SSTL has been building in Guildford, UK, since the early 1980’s. Carbonite-1 launched in 2015 was an innovative development mission based on a commercially available optical telescope.

The range was always designed to be multi-sensor and has evolved to feature a standard set of core platform avionics available now with either a high resolution optical, medium resolution multi-spectral, mid-wave infra-red or SAR payload. CarbSAR — delivering high-resolution, X-band SAR imagery — sees the SAR electronics embedded with the standard Carbonite satellite core avionics in an elegant combination with the stowable OSS antenna.

“This In Orbit Demonstration mission will allow us to build on our relationship with SSTL and accelerate our product development and industrialization program for the game changing Wrapped Rib SAR antenna. The support of NSSIF is a huge vote of confidence in the technology and the capability of Oxford Space Systems to support future UK requirements. I am delighted that the antenna for the IOD mission is being built in our newly commissioned facilities that will establish our production capability for future export sales.”

— Sean Sutcliffe (CEO, Oxford Space Systems)”

“Announcing a new satellite mission is one of the most exciting things we get to do here at SSTL. And that excitement is amplified when the mission in question is CarbSAR, a variant of our Carbonite range, and a mission part-funded by our Shareholder Airbus Defence & Space. CarbSAR is a compelling UK success story on its own, as well as a necessary step towards the bigger spacecraft required for the UK’s Space ambitions. The integration of our latest generation 100Kg Satellite platform and SAR electronics with OSS’s revolutionary wrapped rib antenna is a mission we will be very proud to launch.”

— Andrew Cawthorne, Business Development Director of SSTL

About the companies

Surrey Satellite Technology Limited (SSTL) is at the forefront of space innovation delivering customisable complete mission solutions for Earth observation, science, communications, navigation, in-orbit debris removal and servicing and exploration beyond Earth infrastructure. Since 1981, SSTL has built and launched 71 satellites for 20 international customers, as well as providing training and development programs, consultancy services, and mission studies for ESA, NASA, international governments and commercial customers. SSTL is well known for innovative missions such as the CARBONITE satellites, the NovaSAR S-band radar imaging satellite and the RemoveDEBRIS space debris removal technology demonstrator.

Oxford Space Systems is a venture capital backed, growth stage space technology business founded in 2013 with a vision to be the global leader in deployable antennas for Space. The company continues to grow rapidly in response to commercial contracts secured and currently employs over 70 staff. Oxford Space Systems moved into its own custom-built facility on the Harwell Campus in October 2018. Oxford Space Systems has established a metal mesh manufacturing facility at their Harwell Science and Innovation Campus base, manufacturing foldable surfaces for their reflector antennas. The project, backed by the European Space Agency — ESA ARTES Core Competitiveness programme, will enable the company to meet the growing market demand for high-specification antennas. In January 2023 Oxford Space Systems opened a new manufacturing facility in Abingdon, Oxfordshire to support its ambitious growth plans. The primary objective of this new facility is to scale up internal capability to manufacture composite materials and components for deployable antennas. This will accelerate the company’s industrialisation plan to deliver batches of antennas for customers’ satellite constellation programs.