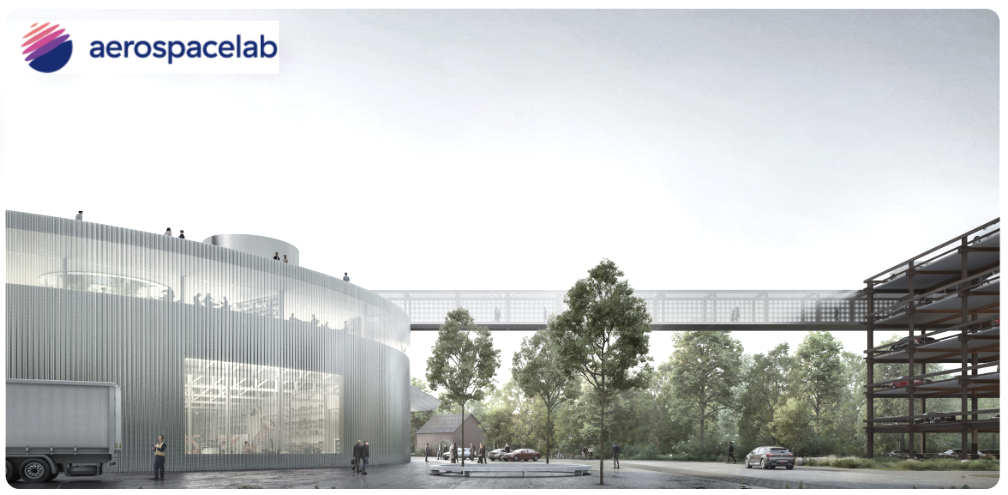

Aerospacelab has unveiled their satellite megafactory commitment, with a yearly production capacity of 500 satellites — this makes this site the largest satellite manufacturing plant in Europe.

This groundbreaking new site, which will be built by Sambrinvest in Charleroi, follows the launch of the company’s Monnet Center facility, located in Ottignies-Louvain-La-Neuve that can produce as many as 24 satellites a year.

Dedicated to generating positive impact globally by making geospatial intelligence actionable and affordable, Aerospacelab has taken a fully, vertically integrated approach. The team is closely involved in satellite design, prototyping, and hardware testing, producing satellites and constellations for a broad range of applications. With these wide-ranging capabilities, Aerospacelab supports decision-making through satellite intelligence in environment protection, sustainable commodity production, agriculture, infrastructure monitoring, security, and more.

Since its inception in 2018, Aerospacelab has been striving to meet the accelerating demand for satellites in the decade ahead. Propelled by its 40 million euro Series B fundraise in February of 2022, the company is already ramping up satellite production capacity, deploying multiple constellations to establish same-day monitoring of the Earth’s surface, and implementing Aerospacelab’s unique geospatial data fusion analytics capabilities. The first satellites will roll off the assembly line at Aerospacelab’s new megafactory by the start of 2025.

According to Euroconsult, by 2030, more than 1,700 satellites every year worldwide are expected to be launched.

Benoît Deper, CEO and founder of Aerospacelab, said, “We’ve been inspired by the automotive industry where standardized products still have the possibility to be customized for specific needs. We are establishing satellite manufacturing plants, complete with production lines using ‘off-the-shelf’ components. Both at the factory in Ottignies-Louvain-la-Neuve and at the megafactory in Charleroi, we own and operate all the testing facilities relevant for satellite manufacturing, which promotes the vertical integration that gives us the edge in agility. Ultimately, we are striving to make the ‘Henry Ford moment’ in satellite manufacturing happen.”