On its next mission set for liftoff later this month, Rocket Lab will try to recover the first stage of its Electron small satellite launcher after parachuting into the Pacific Ocean downrange from the company’s privately-run spaceport in New Zealand, officials announced Thursday.

The attempt to retrieve the Electron rocket’s first stage moves Rocket Lab closer to eventually capturing falling boosters in mid-air with a helicopter, then reusing the hardware. The reuse initiative is aimed at increasing Rocket Lab’s flight rate, and could result in cost savings, according to Peter Beck, the company’s founder and CEO.

Rocket Lab, a California-based launch company, initially planned to try to recover an Electron booster for the first time on its 17th mission. It’s now planning to attempt the feat on the company’s next launch — the 16th flight of an Electron rocket since it debuted in 2017.

Engineers have completed a series of tests since last year, first demonstrating the carbon composite Electron booster can withstand the heating and structural loads of re-entering the atmosphere. Rocket Lab performed the re-entry experiment on two Electron flights in December 2019 and January 2020.

Then the company earlier this year tested the ability of a helicopter to snag a mock-up of an Electron first stage in mid-air. Since then, Rocket Lab completed a series of drop tests of the booster’s parachute system, which Beck said the company developed in-house.

“It’s not very often in the space industry you pull something forward, but this mission we are,” Beck said. “This is a huge milestone mission for us. This is the first time we’re actually going to do everything but capture it under a helicopter. So we will once again re-enter the stage — re-orientate it first — and then re-enter it while maintaining the re-entry corridor.”

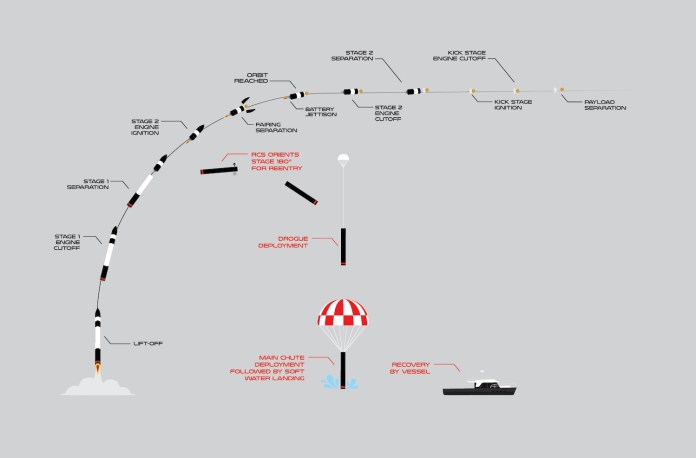

After plunging into the thick, lower layers of the atmosphere — “hitting the wall,” as Beck calls it — the booster will deploy a pilot parachute, a drogue chute, and then a circular main chute. The rocket’s parachutes will “hopefully bring it under a nice stable descent descent and splash it down into the ocean,” Beck said.

Recovery vessels stationed near the booster’s splashdown zone around 250 miles (400 kilometers) south of the launch site will move in to secure the first stage and hoist it onto a ship for return to New Zealand.

“This is kind of an all-up combined test at the conclusion of a number of tests we’ve been going over the last 12 months,” Beck said. “So we’ll look forward to seeing what we’ve really got.”

All of the system tests and sub-scale demonstrations so far have showed Rocket Lab is on track to recover the rocket, Beck said. But this will be the first time engineers put all the systems together on a single test, and then fly the rocket through the atmosphere at hypersonic speed.

“I’ll stop being nervous once we get it back in the factory, but until then I think there’s just a lot that has to work,” Beck said in a conference will with reporters.

The first opportunity to launch the mission — which Rocket Lab has nicknamed “Return to Sender” — will be Nov. 15, U.S. time. There’s a 14-day launch period available for the flight, with the 2-hour, 50-minute window Nov. 15 opening at 8:44 p.m. EST (0144 GMT; 2:44 p.m. New Zealand time on Nov. 16).

The Electron rocket will blast off from Launch Complex 1 at Rocket Lab’s privately-owned spaceport on Mahia Peninsula, located on the east coast of the North Island of New Zealand.

The mission’s primary goal is to carry 30 small satellites into a 310-mile-high (500-kilometer) sun-synchronous orbit.

The nearly 60-foot-tall (18-meter) Electron rocket is sized to carry small payloads into orbit. The kerosene-fueled rocket can deliver about 440 pounds, or 200 kilograms, of payload mass into a 310-mile-high sun-synchronous polar orbit.

The Electron rocket’s nine Rutherford first stage engines will propel the launcher to an altitude of roughly 250,000 feet, or 80 kilometers, in the first two-and-a-half minutes of the flight. Then the Rutherford main engines shut down and the first stage separates, allowing a single engine on the Electron’s second stage to continue the journey into orbit.

After separation, the 40-foot-long (12-meter) first stage will fire control thrusters to flip the booster 180 degrees, putting the rocket in the correct orientation for re-entry.

Aerodynamic drag from the re-entry will slow the rocket’s velocity from about eight-and-a-half times the speed of sound to just below the speed of sound, then the booster will commence the parachute deployment sequence. The rockets flown during the re-entry experiments in late 2019 and early 2020 did not carry chutes.

“Recovery systems, parachutes, are now trivial things to get right,” Beck said. “So whenever you throw out a pierce of fabric just slightly under the speed of sound, it’s alway a little bit interesting.”

If it all works as designed, the rocket will splash down in the Pacific Ocean at a velocity of about 10 meters per second, or about 22 mph. “We don’t expect significant damage from splashdown with the ocean, other than everything getting wet.”

Rocket Lab’s team will place flotation aids around the booster, then install a collar before it is lifted by crane onto the recovery ship.

Engineers are eager to inspect the rocket once it’s back in Rocket Lab’s factory.

“Once we get it back into the factory, it’s like a CSI really,” Beck said. “We’ll pull it all apart and really dig into how well each of the components and the sub-assemblies performed. It’ll be a very time-consuming process to go back and see what we’ve got.”

Beck said the company is taking an incremental approach to proving out its ability to recover and reuse Electron rocket boosters. Engineers want to see how well the booster survives re-entry, and it’s likely Rocket Lab will try several water splashdowns before attempting a mid-air recovery for the first time.

“If we’ve got a smoldering stump, then there’s really not much point in catching a smoldering stump with a helicopter,” Beck said.

Catching the rocket in mid-air will prevent sensitive engine components and other hardware from being contaminated by salty sea water, easing refurbishment between missions, according to Rocket Lab.

In preparation for recovering and reusing hardware, Rocket Lab has modified the Electron booster stage to carry guidance and navigation equipment, an independent S-band telemetry system, an on-board flight computer, a heat shield, and parachutes.

The main goal of the reuse program is to increase Rocket Lab’s launch rate.

“The strongest driver is being able to not have to re-build rockets (for every mission), so being able to increase production rate is really the key driver, even if it’s economically neutral,” Beck said. “The fact that we don’t have to build more vehicles in the same factory is a really big advantage. If we can get it back in wonderful condition, then of course, economically it’s very powerful.

“If you can successfully bring back a first stage and do no to even minimal refurbishment, then you can actually realize a good savings,” Beck said. “We’re a conservative bunch, so we think — at least for a while — there’s going to be some pretty heavy refurbishment and recertification until we get enough confidence and statistics to put something back on the pad with minimal work.

“You’ve probably seen the same thing with SpaceX,” Beck said. “As they’ve matured their recovery systems, they’ve tended to do less and less refurbishment as time goes on.”

SpaceX pioneered rocket reuse in the commercial launch industry, but Rocket Lab is taking a different engineering approach.

The Falcon 9 rocket operated by SpaceX is much larger than Rocket Lab’s Electron vehicle, with enough performance margin for engineers to reserve propellant for propulsive landing maneuvers during mid-air restarts of the Falcon 9’s main engines.

That won’t work for smaller satellite launchers like the Electron, which needs all of its propellant to place payloads into orbit.

Beck said the addition of recovery hardware takes away about 7.5% of the Electron rocket’s overall launch capacity to sun-synchronous orbit. SpaceX takes a bigger performance hit by percentage when it lands a Falcon 9 booster.

SpaceX initially tried using parachutes to recover its Falcon 1 and Falcon 9 boosters, but those attempts didn’t work. The company eventually switched to a design for vertical landings of the Falcon boosters on floating ships in the ocean, or at an onshore landing site near the launch pad.

Although Beck said it’s not Rocket Lab’s short-term goal, reusing rockets can allow companies to slash launch prices. Rocket Lab has already cut the price for a dedicated small launch vehicle.

“We’ve seen the cost of dedicated small launch come from anywhere from $50 million to $30 million for a Pegasus or a Minotaur (rocket) down to $7 million for a Rocket Lab vehicle,” Beck said.

If Rocket Lab is successful with reusing its boosters, “I think we’ll see a dramatic change in pricing again,” Beck said.

Email the author.

Follow Stephen Clark on Twitter: @StephenClark1.

– Advertisement –