HILO, Hawai’i (PISCES PR) — NASA has plans to put humans back on the Moon as early as 2025 and ISRU (in-situ resource utilization) will be a crucial technology for establishing the infrastructure needed to sustain humans in the harsh lunar environment. Using raw, native materials, ISRU can provide vital resources like breathable air, tools or building blocks for shelters.

For years, the Pacific International Space Center for Exploration Systems (PISCES) has been using Hawaiian basalt—a volcanic rock with similar chemical properties to regolith—to develop ISRU methods for building launch pads, berms, roads, shelters and other structures on the Moon and Mars. Much of this work has focused on sintering—using heat to fuse basalt particles into a cohesive, robust material. Structural testing has shown sintered basalt to be stronger than commercial-grade concrete, but the bulk of power required in the sintering process makes it difficult to execute in a lunar environment where energy is a critical, finite resource.

To address this challenge, PISCES and Masten Space Systems are developing a composite material with a binding agent that fuses basalt particles together at much lower temperatures—all within a vacuum or CO2-rich environment. Last year, NASA awarded an STTR Phase 1 grant to Masten Space Systems in partnership with PISCES to develop this low-energy, additive construction method. The project will develop basalt-based launch pad tiles using only materials that can be found on the surface of the Moon and Mars.

“We know it works on smaller sample sizes, the problem is scaling up,” said Christian Andersen, program manager at PISCES. “The tiles we are producing for this project are very large and much more challenging to produce because a lot more moisture must be extracted during the curing process.”

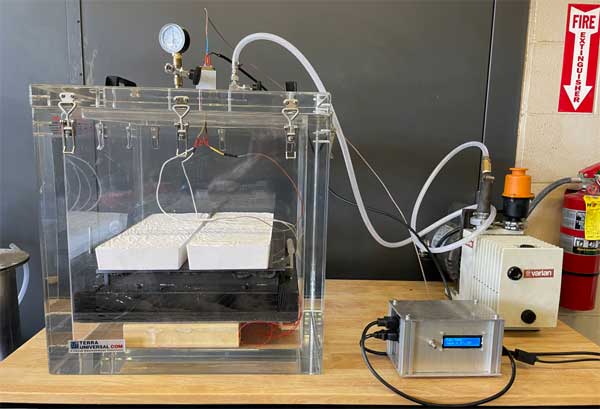

Curing requires a heavy acrylic chamber about the size of a mini-fridge. Using a pump to remove all the air, the chamber provides a lunar-like vacuum environment where the material can dry. An additional pump can fill the chamber with CO2 to mimic Martian atmospheric conditions.

Beforehand, tile-shaped molds measuring one-square-foot are filled with sifted Hawaiian basalt fines. The fines are pre-mixed with a novel binding agent that will fuse them together. Once the mold is set, the chamber is sealed to cure the tiles with the help of a small heating device. Pinpointing the ideal curing time and basalt-binder mix ratio is the most pressing challenge in the project—which will conclude before next summer.

PISCES will produce 16 large tiles for structural testing at the University of Hawaiʻi at Mānoa. Masten Space will also test these tiles, blasting them with a rocket plume to assess their durability as a launch pad material while sintering them in the process.

Under the same project, Masten Space Systems is developing an additive manufacturing extruder that can: 1) build a launch pad using the basalt-based composite and 2) withstand the harsh lunar/Martian environment.

Depending on the results, the project could move into a Phase 2 NASA STTR award to build and test the prototype extruder.