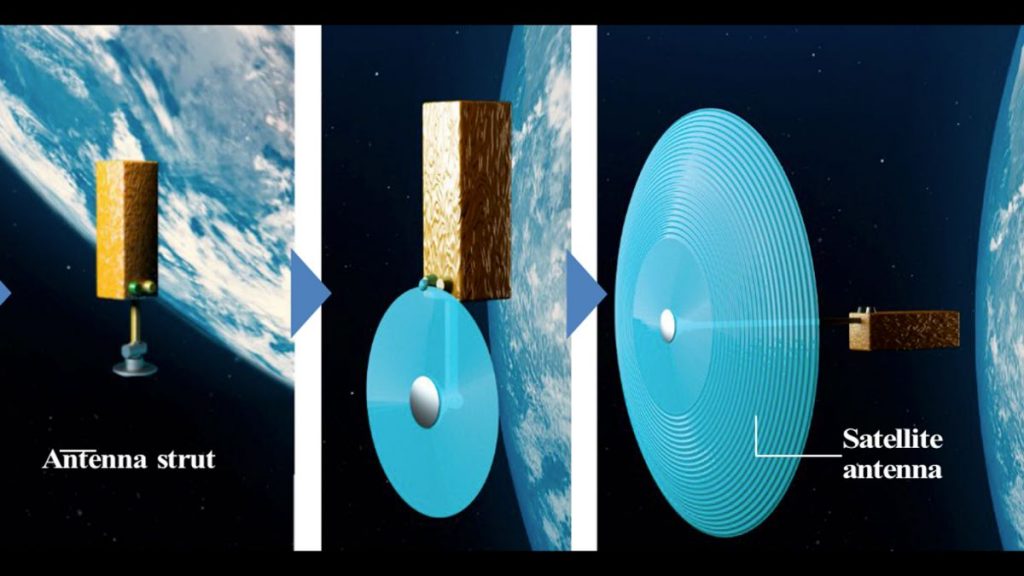

Satellite antennas can be 3D-printed in space with the help of sunlight, using a new patented technique that promises to do away with clunky satellite parts that take up too much space in a rocket.

The new method, developed by Japanese technology company Mitsubishi Electric Corporation, uses a special type of resin that turns into a rigid solid material when exposed to ultraviolet radiation from the sun that is present in space.

The company has so far only demonstrated how the technology works in simulated space-like conditions in a test chamber. Mitsubishi researchers printed an antenna dish 6.5 inches (16,5 centimeters) wide that performed in tests just as well as a conventional satellite antenna.

Related: In-space manufacturing could help humanity fight climate change, startup says

The sensitivity of antennas is directly related to their size; the larger the antenna, the better it detects and transmits its signal. But the size is a problem when launching to orbit, as a large antenna takes up a great deal of space in a rocket fairing. The antennas also need to be sturdy to survive the vibrations during the launch, which makes them heavy. And the heavier a satellite is, the more expensive it is to launch.

Components that are 3D-printed in space can be much lighter and thinner, as they don’t have to withstand the vibrations of launch.

So, by 3D-printing antennas directly in space, operators would not only save money, as their satellites would be lighter, they would also be able to fit much smaller satellites with much larger antennas than they can today.

The technology, the company said in an emailed statement, paves the way for the “3D printing of very large structures in space,” which wouldn’t fit into a rocket fairing at all.

The photosensitive resin is also heat resistant and can survive in temperatures of up to 750 degrees Fahrenheit (400 degrees Celsius), which is higher than what spacecraft experience in orbit around Earth.

“Spacecraft antenna designs are challenging due to their conflicting requirements for high gain, wide bandwidth and low weight,” the company said in the statement. “High gain and wide bandwidth necessarily require a large aperture, but economical orbital deployment conventionally dictates that designs be lightweight and small enough to fit or fold inside a launch vehicle or satellite deployment mechanism.”

The company added that its resin is the first suitable for use in a vacuum, as it doesn’t require atmospheric oxygen to prevent it from turning solid too quickly. And the use of natural ultraviolet light reduces the power consumption of the 3D printer, Mitsubishi representatives added.

Follow Tereza Pultarova on Twitter @TerezaPultarova. Follow us on Twitter @Spacedotcom and on Facebook.